Irradiation facilities

The fission of uranium initially supplies fast, i.e. high-energy neutrons. However, most experiments and the actual chain reaction for the production of neutrons require lower-energy thermal neutrons (<0.6 eV). To achieve this, the neutrons are slowed down by collision with the surrounding heavy water.

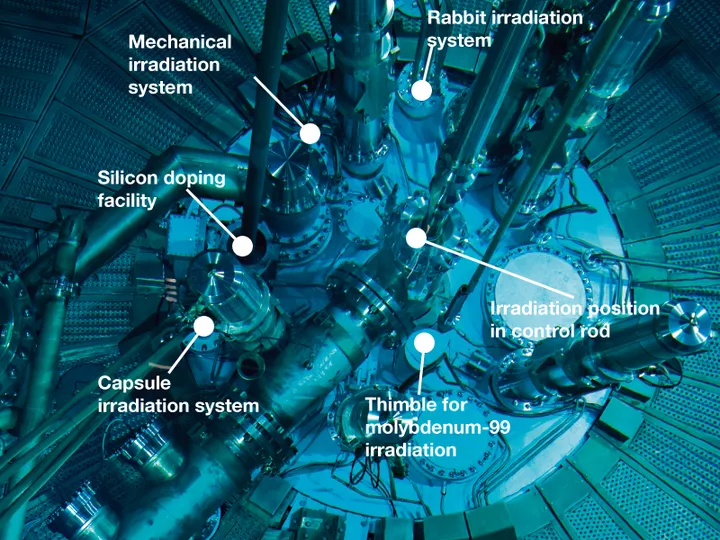

The FRM II is equipped with a series of irradiation facilities which cover a wide range of applications:

- Rabbit Irradiation System (RPA)

- Capsule Irradiation System (KBA)

- Mechanical Irradiation System

- Silicon Doping Facility

- Irradiation Position in the Control Rod

- Irradiation with fast neutrons at the instruments MEDAPP and NECTAR

- Irradiation with cold neutrons at the instrument PGAA

In addition, an ongoing project at the FRM II aims to provide an irradiation facility for uranium targets, which are the basis for the production of the medically important radioisotope Mo-99 / Tc-99m.

Apart from the beam tube instruments MEDAPP, NECTAR and PGAA, all irradiation facilities have an irradiation channel permanently mounted in the moderator tank, which can be loaded or unloaded with samples while the reactor is running,.

Applications

Materials are irradiated for various purposes: At FRM II, among other objectives, silicon is doped for high-performance electronics. To this end, the monocrystalline silicon ingots are placed for a period of anything from a few minutes up to a day in a special device in the irradiation position within the moderator tank. The neutrons convert individual silicon atoms into phosphorus. With the use of this doping technique the conductivity of the semiconductor material silicon may be increased in a precise way and, due to its particularly homogeneous doping profile can be used for high-performance electronics e.g. in DC power converters.

Radioisotopes for industrial and medical applications are generated in other irradiation facilities of the FRM II. A particularly important example is Lutetium-177 for the pharmaceutical industry, which is already routinely used in the treatment of tumors in hospitals nationwide.

Another application of neutron irradiation is the preparation of samples for neutron activation analysis (NAA). This technique offers the possibility of accurately determining the elemental composition of a suitable sample. NAA can evidence one atom in a trillion for some elements.

Technical Data of irradiation facilities

| irradiation facility | posi- tions | thermal neutron flux density | relation thermal/fast neutron flux density | max. sample size | irradiation time | applications |

|---|---|---|---|---|---|---|

| rabbit irradiation | 6 | from 5 · 1012 to 4 · 1013 cm-2s-1 | 1300 – 60000 | 12 cm3 | seconds - hours | production of radioisotopes, neutron activation analysis |

| capsule irradiation | 2 x 3 | up to 1.3 · 1014 cm-2s-1 | 330 – 770 | 30 cm3 | minutes - weeks | production of radioisotopes, neutron activation analysis |

| mechanical irradition | 1 | 1.1·1013 cm-2s-1 | ~1200 | 2.5 l | max. 2h | e.g. geo-chronology |

| irradiation in the control rod | 1 | 2·1014cm-2s-1 | - | ≈ 2 cm³ | 60 days | production of radioisotopes |

| silicon doping | 1 | 1.7 ·1013 cm-2s-1 | - | height up to 500 mm, diameter up to 200 mm | silicon doping | |

| gamma irradiation | se- veral | 1 kGy/h to 100 kGy/h | - | diatmeter up to 85 mm, height up to 1 m | minutes - weeks | materials science, geological analyses |

| irradiation with fast neutrons at MEDAPP | 1 | to 5·109 cm-2s-1 fast neutrons | - | to be defined from case to case | material testing with fast neutron irradiation | |

| irradiation at the instrument PGAA | 1 | to 1.6 · 1010 cm-2s-1 | - | 40 × 40 x 40 mm3 | analytical analyses |