Objectives of the conversion

Above and beyond the target of enrichment below 50% laid down in the federal-state agreement and the operating license for the FRM II, international efforts are being made, in particular by the International Atomic Energy Agency (IAEA) and the US Department of Energy (DOE), to convert research reactors exclusively to low enriched uranium (LEU, <20% U-235 enrichment).

For this reason, as well as for the sustainable fulfillment of the objectives mentioned above for conversion, TUM has always strived to convert to the lowest possible enrichment. The aim is, therefore, to convert the FRM II to a fuel element with <20% uranium-235 enrichment (LEU).

Proliferation - worldwide endeavor

Research reactors are the only civilian facilities that have used, and in some cases still use, highly enriched uranium (HEU). The aim of converting every research reactor is to minimize potential residual proliferation risks by reducing the uranium-235 enrichment in the fuel used.

Requirements: high neutron flux for science and safety aspects

The reactor shutdown, unavoidable with every conversion, causes scientific cutbacks, interruption of isotope production, essential for nuclear medicine, and high costs. It is therefore necessary to achieve this goal sustainably and in a single step.

Concrete objectives for the conversion:

- Maintaining the current safety level

- Maintaining scientific performance

- Rapid conversion in as few steps as possible without long downtimes

- Sustainable fulfillment of the retrofitting agreement, in the sense of non-proliferation

- Securing the future viability of the FRM II

Measures: higher density

A fuel suitable for converting the FRM II is not yet used worldwide. In international cooperation with France, Belgium, and the USA, among others, TUM has been working since 2003 on developing, producing, and qualifying such fuels. It is developing suitable reactor core designs to convert the FRM II.

Reducing the uranium-235 enrichment in the fuel element while maintaining the core geometry and scientific performance is only possible by increasing the fuel volume and the uranium density, which is only possible to a limited extent. For example, reducing a 93% uranium-235 enrichment to 20% requires an increase in uranium density by a factor greater than five, partly due to the increased neutron absorption by uranium-238.

Three material variants have been identified in the past which, in principle, appeared to be suitable for retrofitting the FRM II:

- high-density uranium silicide

- dispersed U-Mo

- monolithic U-Mo

The decision in favor of LEU fuel has been made: The FRM II will be converted to monolithic uranium-molybdenum.

Decision for monolithic U-Mo

Monolithic U-Mo

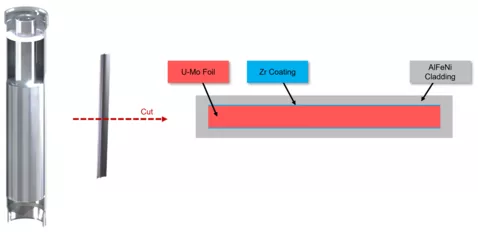

Since the achievable uranium density of dispersed U-Mo for some high-power research reactors such as the FRM II is still insufficient to achieve uranium-235 enrichment < 20 % (LEU), monolithic fuels have been developed as an alternative to the common dispersed fuels. Here, the matrix material aluminum is completely omitted and the fuel is in the form of a metallic foil within the fuel plates. Monolithic U-Mo is an alloy with a molybdenum content of 10.0 wt.% and a nominal uranium density of 15.5 gU/cm³.

Test irradiations

The most recent irradiation tests of the monolithic U-Mo fuel are the EMPIrE test (organized by the HERACLES consortium, partially funded by the US DOE) and the MP-1 test (organized by the US DOE) at INL's ATR reactor. Here, numerous mini-size LEU fuel plates were irradiated using European and U.S. fabrication techniques under high-power research reactor conditions. During the non-destructive and destructive post-irradiation studies, no evidence was found that would cast doubt on the general qualifiability of this fuel.

Fabrication of the fuel plates

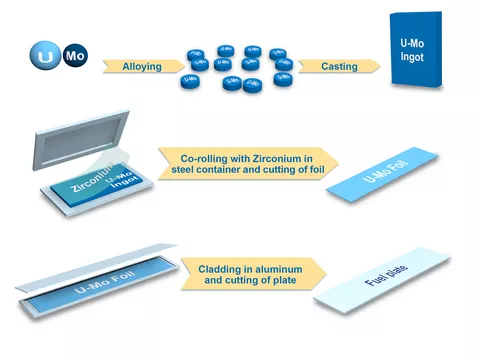

The fabrication of fuel plates based on monolithic U-Mo is very different from the fabrication process of fuel plates based on dispersed fuels. After the alloying process, the U-Mo is first cast into a rectangular shape ("ingot"), which is then hot- and, if necessary, cold co-rolled with a Zr interlayer into a thin foil, which is then cut rectangular. The U-Mo foil produced in this way is then processed into a fuel plate using a Framatome-CERCA proprietary process ("C2TWP").

The task now is to put the theoretically established convertibility, which has been confirmed by independent teams of experts, into practice. To this end, a cross-departmental project team at FRM II will carry out further optimizations to the fuel element design in the next few years and prepare the initiation of the licensing procedure and the procurement of new fuel elements. Accompanying the technical and nuclear law implementation, the research work that continues to be necessary will be carried out at the TUM Center for Nuclear Safety and Innovation.