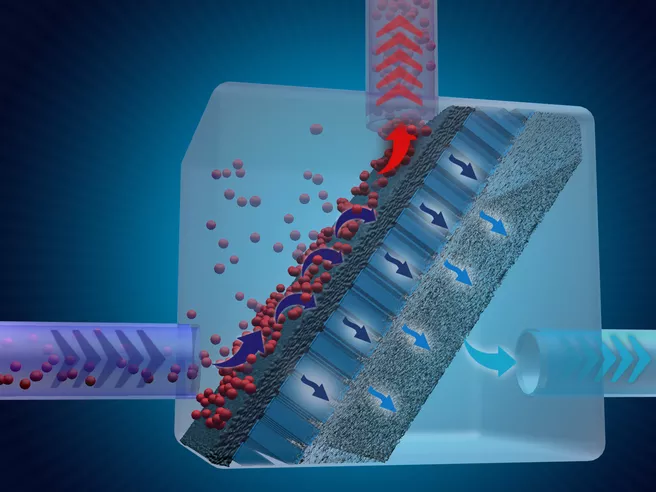

Water is a precious resource. When there is not enough fresh water available, water treatment plants purify both brackish groundwater and wastewater for domestic use and to make it drinkable. Huge plants filter the pretreated water through selective membranes that remove unwanted organics, colloidal particles, and salts from the water.

Filters clog

Minerals such as silica (SiO2), organic and biomaterials often clog these membrane filters, which is referred to as scaling and fouling respectively. This reduces the amount of water that can be cleaned by the membrane in a given amount of time. As a result, the membranes must be cleaned with special agents or replaced more frequently, which is costly.

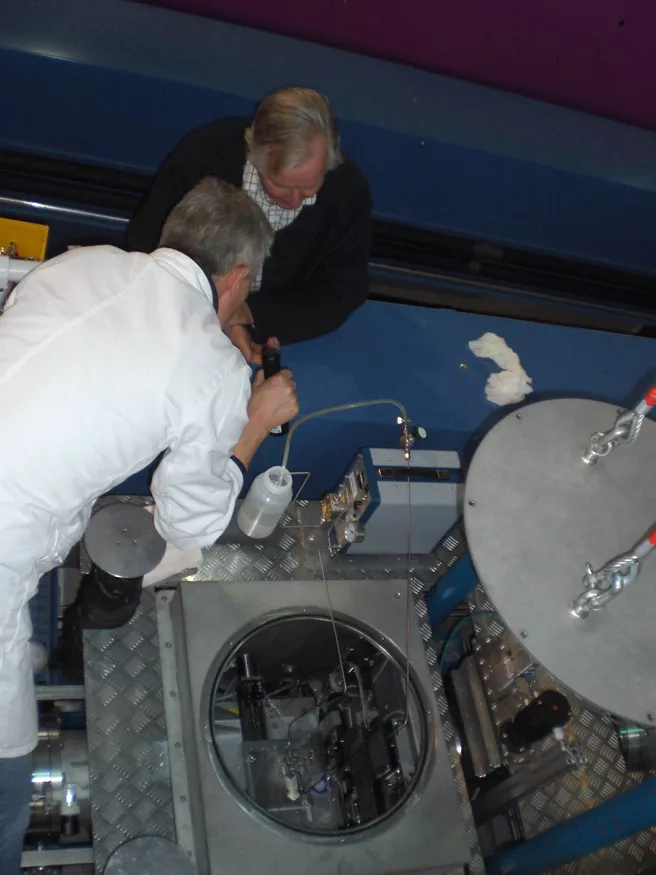

Israeli and German researchers have now built a special cell for these membranes to simulate the deposition processes that cause the clogging and fouling. This cell meets the requirements for performing filtration experiments using in-situ small-angle neutron scattering on the KWS-3 and KWS-1 instruments at the Heinz Maier-Leibnitz Zentrum. This method makes it possible to analyze fouling and scaling layers down to the nanometer scale.

Cake layer in front of the membrane

"We were able to simulate the entire process and follow how it happens in reality," says Dr. Dietmar Schwahn of Forschungszentrum Jülich. "The neutrons show us non-destructively how silica particles accumulate in front of the membrane." In many cases, the particles form a "cake" layer on the membrane surface, where they are ordered as a dense silica crystal. Using neutron scattering, the researchers were able to determine the distance between the silica particles within this layer. Surprisingly, this "cake" formation resulted in a slightly increased water flow rate, which was determined in parallel with the neutron measurements.

Low-cost substances prevent fouling and scaling

Neutrons showed what happens on the scale of micrometers to nanometers on membrane surfaces in wastewater treatment plants. "Engineers measure the flow of water through the membranes," says Dietmar Schwahn. "We have now helped explain the influence of silica particles on water flow through the membrane."

"The results will now help to develop cost-effective methods and substances that lower the fouling and scaling rate of the membranes" says Prof. Dr. Yoram Oren of the Zuckerberg Institute for Water Research at Ben-Gurion University in Israel.

Original publication:

V. Pipich, T. Starc, J. Buitenhuis , R. Kasher, W. Petry , Y. Oren, D. Schwahn, Silica Fouling in Reverse Osmosis Systems–Operando Small-Angle Neutron Scattering Studies, Membranes 11, 413 (2021)