The typically used shielding material in neutron research facilities all around the world is borated heavy concrete. It attenuates both gamma and neutron radiation to shield the outside from the radiation at the instrument. Due to its high iron content, the typical density of this heavy concrete reaches 3.5 to 4.5 tons per cubic metre or more, causing a considerable total weight for instrument shielding. Since not only space but also permitted floor load is limited in most facilities, it is desirable to reduce the size and mass of the shielding material.

To overcome these disadvantages, Elbio Calzada, Burkhard Schillinger, Harald Türck and Florian Grünauer have developed a new shielding material composed of a mixture of steel granules, ferroboron granules and liquid paraffin. The material has and maintains the consistency of wet sand and does not solidify. It is used in the rebuilt ANTARES facility.

The neutron beam SR4B originally hosting ANTARES is the only beam providing a cold spectrum that can be extended from the experimental hall of the FRM II to the new neutron guide hall east, so ANTARES had to move to the second channel SR4A of the beam tube SR4. When planning the new geometry of the radiography and tomography facility ANTARES, the team had to cope with increased weight and space constraints due to the additionally required shielding for the second beam channel. By Monte Carlo simulations, the team optimized the composition for the boron and hydrogen content.

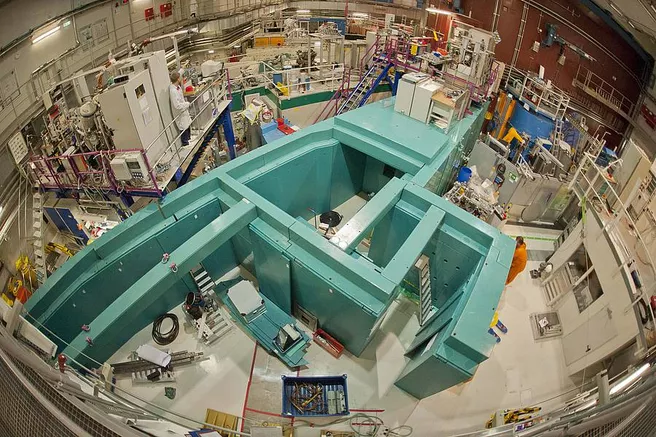

The new green steel containers for the new ANTARES facility have now been filled by the moist powder mixture. As it does not become solid, it can be removed from the steel containers and reused when the facility has to be modified or dismantled in the future.

Since the new material contains only elements contributing to the radiation shielding, the thickness of the shielding can be reduced by 20 percent compared to heavy concrete, saving more than 50 tons of weight in the case of ANTARES. Though the initial expense for the shielding material is 10-20 percent higher than for heavy concrete, it comes definitely cheaper in the long term perspective as it can be reused, saving the original investment, and thus does not cause additional waste disposal costs. The Technische Universität München has patented this invention and would welcome a partner in industry to industrialize the filling of the steel containers for custom shielding.

The old heavy concrete shielding of the ANTARES facility has mostly been recycled: About 200 tons of components will be reused at the neutron facility of the Institut Laue-Langevin (ILL) in Grenoble, and some shielding walls are reused by the FRM II instrument MEPHISTO in the neutron guide hall.

Original publication: Reusable shielding material for neutron- and gamma radiation, E. Calzada, F. Grünauer, B. Schillinger, H. Türck, Nucl. Instr. and Meth. A, Volume 651, Issue 1, 21 September 2011, Pages 77-80 , doi: 10.1016/j.nima.2010.12.239