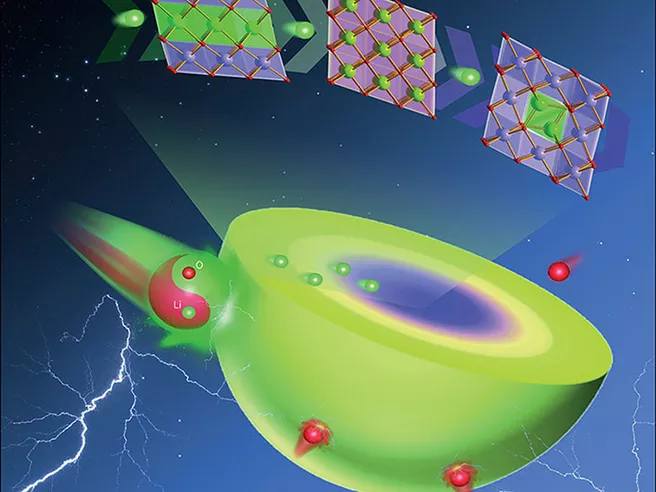

A clear trend towards reduction of cobalt in Li-ion batteries can be observed over the last decade. Cobalt forms a part of battery cathodes, but is costly, highly reactive and also geographically limited, where it is often mined under conditions that violate human rights. Tremendous efforts have been undertaken to reduce the amount of cobalt in Li-ion batteries, which has resulted in mixed nickel-cobalt-manganese (NCM) or nickel-cobalt-aluminum (NCA) cathodes being commonly used in Li-ion cell technology. The cobalt-free battery is the next target, and this is currently under active development. Co-free Li-excess layered oxides are considered as potential cathode material as they have higher capacities and operate at higher discharge rates.

A group of researchers from the Karlsruhe Institute of Technology, the Forschungszentrum Jülich, the Technical University of Munich (Germany), the Sichuan University (China), the University of Wollongong (Australia), together with scientists from DESY (Hamburg) and ALBA (Barcelona) Synchrotron facilities, has proposed a practical method of controlled synthesis of cobalt-free lithium-excess layered cathode materials. They have also investigated the formation process, incorporation of lithium and oxygen in the host matrix, and effect of synthesis conditions on the electrochemical performance.

"These compounds are a promising candidate to be used as cathodes in the next generation of lithium-ion batteries because they operate at high voltages and deliver high capacities. That means that smaller batteries could deliver more energy”, says Björn Schwarz, researcher at the Karlsruhe Institute of Technology.

At the MLZ, the researchers used the high-resolution neutron powder diffraction at the instrument SPODI for the localisation and quantification of lithium and oxygen in the structure. These investigations help the researchers with a profound analysis of the relationship between electrochemical properties and the structure of the materials.

Original publication:

Hua et al. (2019): Lithium/Oxygen Incorporation and Microstructural Evolution during Synthesis of Li‐Rich Layered Li[Li0.2Ni0.2Mn0.6]O2 Oxides, Advanced Energy Materials, DOI: 10.1002/aenm.201803094