There is one major challenge in the development of more sustainable plastic alternatives for packaging materials: "Packaging should prevent, as much as possible, any exchange of substances between the product and the external environment," is how Dr. Marcel Dickmann, instrument supervisor at the Positron Source NEPOMUC at MLZ, sums it up. Materials based on novel biopolymers are often highly permeable to various gases, including air. As a result, whatever is packaged is either not sufficiently protected, dries out, or in the worst case it spoils. At the Heinz Maier-Leibnitz research neutron source, a German-Italian research team has now investigated how gas permeability can be reduced.

Organic packaging with cotton

To achieve this, the scientists combined lactic acid-based biopolymers in varying proportions with nanoparticles, some of which are obtained from cotton. The finished composite material has the advantage that it is not only completely biodegradable, but also does not require petroleum and instead relies on renewable resources. A multiple win for the environment.

"We were able to show that the properties of biomaterials in general can be changed in a specific way if we add nanocellulose from cotton. For the specific biopolymer (polylactacide) we studied, we were able to determine the exact proportion of nanocellulose at which permeability for gases is lowest," says Dickmann.

Antimatter measures pore size

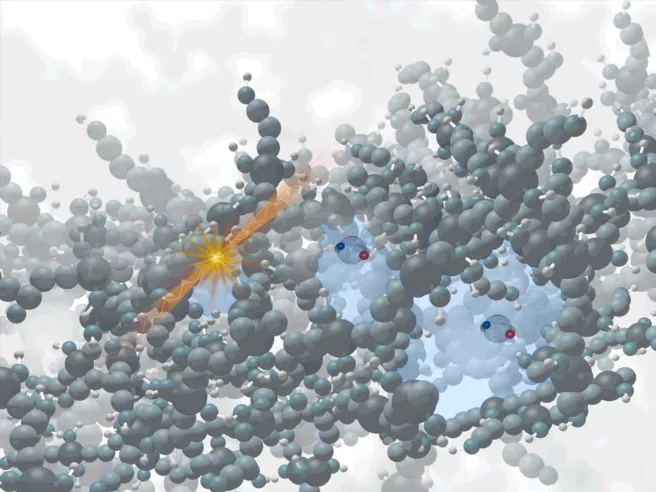

"Antimatter is what many people think of as science fiction," Dickmann elaborates, "but it's actually something quite real." At the NEPOMUC instrument, scientists use neutrons to generate positrons, the antiparticles of electrons. They use them to irradiate their sample material. The survival time of the positrons in the material gives the researchers information about various properties of the sample.

"In porous materials, there is a special intermediate step. In a pore, positrons can combine with electrons and form so-called positronium. In principle, the longer the positronium survives, the larger the pores are," Dickmann explains. He and his team were thus able to determine the pore size and therefore also the permeability for gases with the help of antimatter.

Packaging becomes more easily compostable

The researchers' findings are helping to develop more sustainable alternatives to plastic that nevertheless offer the same level of protection for the product. This is important so that the novel materials can be used commercially on a large scale in the future. The potential applications are diverse, as Marcel Dickmann explains, and the material can be as thick or as thin as desired. Thus, In the future it may be possible to simply dispose of all packaging on the compost heap.

Original Publication

Marcel Dickmann, Stefania Tarter, Werner Egger, Alessandro Pegoretti, Daniele Rigotti, Roberto Sennen Brusa, and Riccardo Checchetto.

Interface nanocavities in poly (lactic acid) membranes with dispersed cellulose nanofibrils: Their role in the gas barrier performances (2020).

Polymer. Volume 202.

DOI: 10.1016/j.polymer.2020.122729