If water is found dripping from the ceiling of the aircraft cabin as its coming in for a landing, it's just one of the many unpleasant side-effects of excessive moisture in the fuselage insulation. Physicists from the Technische Universität München (TUM) and engineers from Hamburg University of Technology (TUHH) recently used neutrons to study a section of an aircraft's skin during a simulated transatlantic flight. At the TUM's Heinz Maier-Leibnitz neutron source (FRM II) the scientists wanted to find out where and how moisture gets into an aircraft's insulation with a view to avoiding the phenomenon in the future.

Dry air in an aircraft is very unpleasant for many passengers. However, it is absolutely vital for safety. That's because moist air penetrates through the cabin into the insulation in the aircraft belly and condenses as water or ice on the cold outside wall. "The many hundred kilograms of water that gather there from the breath of the passengers are as heavy as several passengers," explains Dr. Burkhard Schillinger, who carried out the neutron study of aircraft insulation at the FRM II. The water freezes or sloshes around uncontrolled in the belly of the plane during the flight, which can have a negative effect on flight stability. "And the plane carries the additional weight around with it, unnecessarily each time," says Schillinger.

The insulation also suffers under the effects of the moisture: it insulates less well, and mold can form. At worst, the electrical system inside the aircraft skin could even short-circuit. "At present, an aircraft's insulation needs to be replaced every one to two years," says Andreas Joos, an engineer at the Institute for Thermo-Fluid Dynamics at the TUHH. The problem of moisture in aircraft insulation has been known for about 20 years, and research into the subject has been underway for more than 10 years at Hamburg University of Technology. In the early days, the melting water even dripped onto the passengers during the landing approach. Now, though, there are special insulating materials and a sophisticated drainage system in the aircraft fuselage. After the landing, the majority of the melted water is pumped out. "But it doesn't work in every last nook and cranny of the plane," explains Burkhard Schillinger. A lot of water is left behind in the aircraft's underbelly.

This is one of the reasons why the TUHH is working together with the TUM to find ways of better draining off the water from the aircraft belly. "That’s why it's important to know exactly how the water condenses; whether it stays in liquid form as it takes its detour or whether it freezes straight away. And we wanted to know where it collects: in the insulation itself or on the outside wall?” says Joos.

In an attempt to track down the water in an aircraft, the TUHH teamed up with a partner from industry to conduct a neutron study on the insulation using the ANTARES (Advanced Neutron Tomography and Radiography Experimental System) instrument at the FRM II in Garching. On a test rig at the TUHH they are simulating an aircraft skin with moist air being fed over it, stimulating the breath of passengers. "We can use this to simulate all of the temperature and moisture levels encountered during a transatlantic flight," explains Burkhard Schillinger.

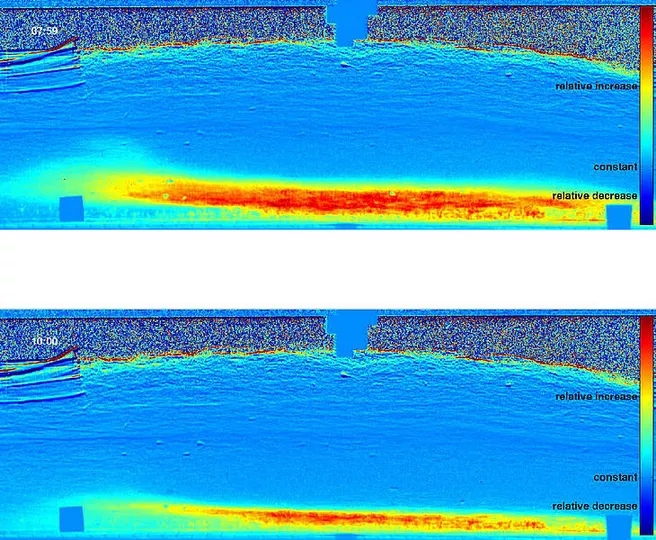

The neutrons of the FRM II at the TUM reveal the precise locations of water or ice during the climbing phase, flight, descent and ground phase. "We initially thought of using conventional measuring techniques from structural physics, but the resolution they provide is not high enough. With neutrons, we see a great deal more," says Joos. The neutrons from the reactor hit the various materials in the aircraft skin; water is the one that slows them the most. The ANTARES instrument uses a special camera to produce images rather like X-rays, which depict – in high resolution – the distribution of water in the insulation.

Initial results show that the distribution of water can be measured easily. The insulation absorbs a lot of moisture during the takeoff phase in particular. "For us it's important to see the increase in moisture over time," says Andreas Joos from the TUHH. The scientists will then be able to find out whether the moisture disperses sooner if the plane stays on the ground a half hour longer, for example.

The next thing the Hamburg-based researchers want to do is build a model and test it at the FRM II in Garching: an aircraft skin with a window, for example, and one with a support strut. Because as they know, water condenses on different constructions in different ways. They also plan to test new insulation materials.

pictures:

http://mediatum2.ub.tum.de/node?cfold=804170&dir=804170&id=804170

articles in the media: