Analysis with neutrons

Thanks to the high neutron flux, the FRM II with its 26 unique instruments offers a diverse portfolio of analytical investigation methods for simple to very complex materials. The experiments can be carried out on samples on the entire length scale from 10-10 m up to component sizes of several decimeters.

Typical methods used here include

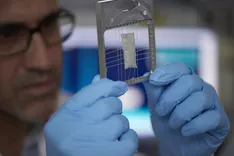

- Neutron radiography

- Neutron tomography for imaging (2D and 3D)

- Diffraction for phase analysis and residual stress measurement

- Small-angle scattering to determine nanoscale objects

- Neutron depth profile analysis for lithium distribution on the surface

- Prompt-gamma-activation analysis for the measurement of trace elements.

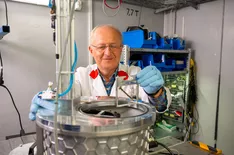

Very special sample environments (furnaces, testing machines, potentiostats, electric fields, magnets, gas atmospheres, hydrogen loading station) can easily be used to support in-situ and operando studies.

In addition, radioisotopes can be produced in the irradiation facilities or the doping of samples can be offered.