Mock-ups of the future Mo-99 irradiation facility

Until the start of irradiation, however, substantial development work is still required. This includes, amongst other things, the completion of two test stands, which represent the essential components of the future irradiation facility built on a scale 1:1. They serve to verify the technical construction, to test the manufacturability of the irradiation channels, and finally to test the handling steps during the irradiation.

Simulation of the cooling channel return flow

The smaller of the two experimental mock-ups is a replica of the cooling channel return flow, which will later house the targets for irradiation. The channel has original dimensions, but is only 2 m long and made of Plexiglas so as to be able to observe the flow of the cooling water. Using dummy targets the behavior at high volume flow is investigated here.

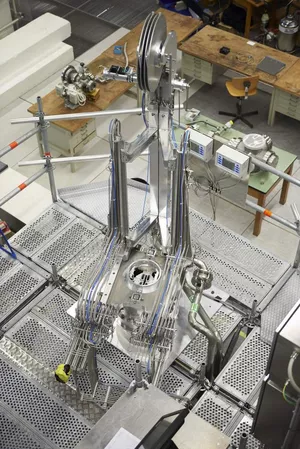

Simulation of the entire Mo-99 irradiation facility

The large experimental mock-up is the replica of the complete cooling channel unit with the two irradiation channels as they are to be introduced later in the already mounted moderator tank thimble. For reasons of cost, the channels are made up out of stainless steel and not Zircaloy as they will later. This experimental mock-up is used to test loading and discharging procedures of the targets as well as cooling processes.