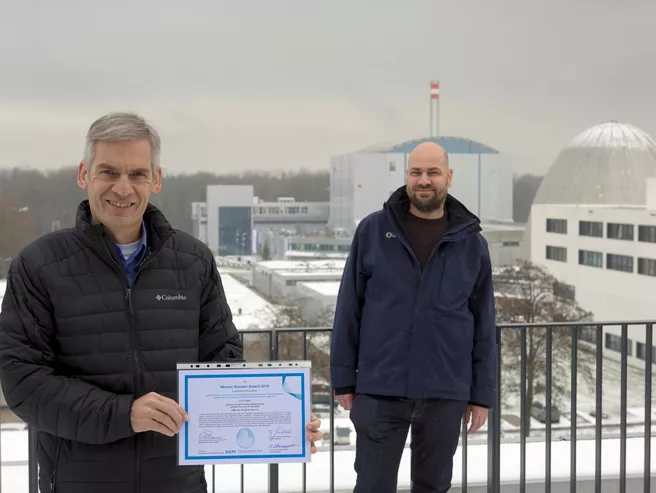

Dr. Ralph Gilles, head of the Advanced Materials group, and Dr. Markus Hölzel, scientist at the SPODI instrument, together with their colleagues from the University of Siegen, TU Braunschweig, and the Nuclear Physics Institute Rez (Czech Republic) received the Werner Köster Prize for their publication "Effect of Cr and Ni on the microstructural evolution in Co-Re-Cr-Ni alloys".

Since 1992, the German Materials Society (DGM) has been awarding the Werner Köster Prize together with Carl Hanser Verlag. It honors an outstanding article published in the International Journal of Materials Research (IJMR), formerly Zeitschrift für Metallkunde. Each year, the editorial board of the IJMR selects a publication from the previous year "that focuses on fundamental, original work in the field of materials science," DGM says on its website.

The prize is named after Professor Dr. Werner Köster (1896-1989), a German chemist and long-time director of the Max Planck Institute for Metals Research in Stuttgart.

Stable and extremely heat-resistant: Development of a new turbine material

The award-winning publication deals with a cobalt-rhenium alloy with nickel and chromium - a promising material for stationary gas turbines and aircraft turbines. "We looked systematically at the effect of chromium and nickel on the stability of the phases present in the material," explains Dr. Markus Hölzel, a scientist at MLZ. The researchers' goal: to develop a material that can withstand the highest possible temperatures. "The higher the temperature at which turbines can be used, the more efficient they are. This is highly relevant because it can reduce CO2 emissions," adds Dr. Ralph Gilles, industry coordinator at MLZ.

Specifically, the researchers were able to use neutrons to describe the influence of chromium and nickel in the cobalt-rhenium alloy in samples the size of coins. The SPODI neutron powder diffractometer made it possible to observe structural phase transformations during heating to 1400°C and subsequent cooling.

Broad spectrum of methods

In the DGM's explanation for the award, the "consistent application of a broad spectrum of complementary experimental and theoretical methods" is particularly emphasized. Furthermore it says that what the scientists discovered in their experiments is an important basis for future materials design.

The award as a brilliant ending to a successful project

Gilles and Hölzel agree that the diversity of methods is the beauty of this work - and it was only possible with an interdisciplinary team. "We have been working with some of the people involved in this field for many years. So I'm very pleased to receive this award," Hölzel emphasizes.

"The publication that received the award is the last within an extremely successful project with many publications. This award is now the icing on the cake, so to speak," Gilles is pleased to say.

____________________________________________________________________________________________

Original publication

Katharina Esleben, Bronislava Gorr, Hans-Jürgen Christ, Christian Pritzel, Debahis Mukherji, Joachim Rösler, Premysl Beran, Pavel Strunz, Markus Hoelzel, Ralph Gilles. (2019). Effect of Cr and Ni on the microstructural evolution in Co–Re–Cr–Ni alloys. International Journal of Materials Research. 110. 1092-1104. DOI: 10.3139/146.111855.

Further information

Werner Köster Prize of the DGM

Further award winners:

- Katharina Esleben, Institut für Werkstofftechnik, Universität Siegen

- Bronislav Gorr, Institut für Werkstofftechnik, Universität Siegen

- Prof. Dr. Hans-Jürgen Christ, Institut für Werkstofftechnik, Universität Siegen

- Dr. Christian Pritzel, Institut für Bau- und Werkstoffchemie, Institut Siegen

- Dr. Debashis Mukherji, Institut für Werkstoffe, TU Braunschweig

- Prof. Dr. Joachim Rösler, Institut für Werkstoffe, TU Braunschweig

- Přemysl Beran, Nuclear Physics Institute der Czech Acydemy of Sciences und European Spallation Source ERIC

- Dr. Pavel Strunz, Nuclear Physics Institute der Czech Acydemy of Sciences