The "organic" in organic solar cells means in this case that the active layer of the solar cell is composed from only organic (e.g. carbon) compounds. For this application it is polymers, which are commonly referred to as plastics. The use of polymers offers many advantages over conventional solar cells made of silicon. "They are cheaper and more environmentally friendly because they are made from a solution and no silicon has to be melted at high temperatures," says Dominik Schwaiger from the TUM Chair of Functional Materials of Prof. Dr. Peter Müller-Buschbaum, scientific director of the Heinz Maier-Leibnitz Research Neutron Source (FRM-II) and Heinz Maier-Leibnitz Center (MLZ), who is researching the topic.

Making organic solar cells from a solution means they can be applied as a thin layer to almost any surface. As a result, they can capture sunlight not only on the roof of a house, but also on large window fronts of high-rise buildings, or on a rollable sheet for portability. What is still missing is efficiency. Organic solar cells do not achieve the performance of conventional solar cells, yet, and are less stable. Therefore, researchers have set themselves the task of making further progress with organic solar cells so that they can be produced on a large scale by industry.

Like two interlocking brushes

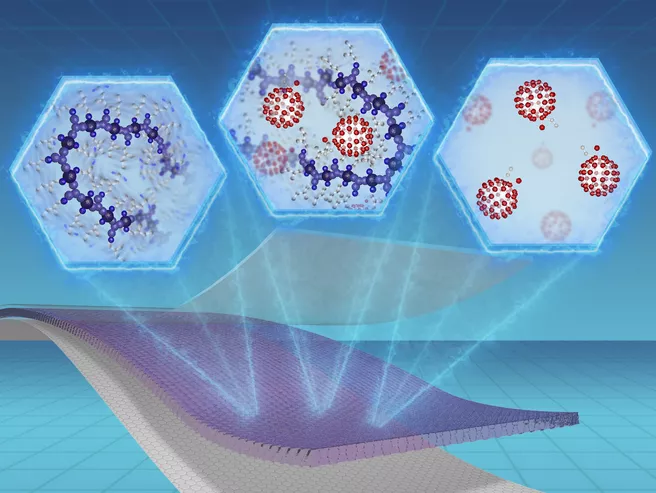

An organic solar cell consists of three key layers: At the top and bottom, electrodes pick up the voltage and in between lies the active layer. The active layer absorbs the incident light and converts it into electricity, which in turn is transported to the end user via the electrodes. The exciting processes happen in the active layer, which is composed of two polymers, PTB7 and PCBM. "You can think of it as two brushes interlocking," explains Dominik Schwaiger. One polymer is responsible for absorbing light and binding the charge, while the other polymer separates the charge from the material and passes it on to the electrodes.

The right mixture

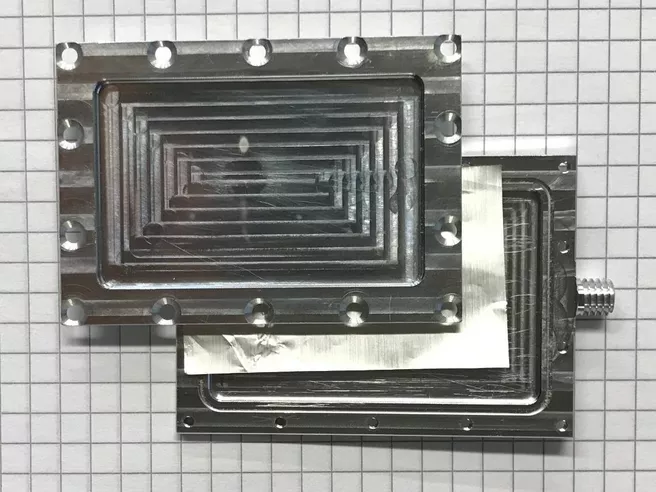

The interesting question now is how the polymers behave in the active layer, because this influences how good the conductivity is and how much the solar cell wears out over time. The polymers used here are long molecular chains with shorter branching side chains. To study the motion of these side chains in more detail, the time-of-flight spectrometer TOFTOF at the Heinz Maier-Leibnitz Center was used. "Neutron spectroscopy is useful in this case, since neutrons are particularly good at detecting hydrogen atoms that appear in the polymer chains," says Dominik Schwaiger.

From these studies, the researchers have learned how the active layer behaves at different temperatures and different mixing ratios of the polymers. This could mean that the not-too-distant future, we may be charging cell phones with power generated from windowpanes.

Original publication:

Dominik Schwaiger, Wiebke Lohstroh, and Peter Müller-Buschbaum: Investigation of Molecular Dynamics of a PTB7:PCBM Polymer Blend with Quasi-Elastic Neutron Scattering.

ACS Applied Polymer Materials 2020 2 (9), 3797-3804

DOI: 10.1021/acsapm.0c00455