Monitoring the facility

Fixed and mobile measuring points are located on the FRM II site to monitor activity within the plant and to monitor emissions. All relevant measured values can be queried via the operational control technology. In addition, the measured values are transmitted to the Bavarian State Office for the Environment (LfU) via the Bavarian nuclear reactor remote monitoring system (KFÜ), which is operated by the LfU.

It is used both for official supervision of the plant and for the early detection of faults.

Contamination monitoring

Local dose rate

The local dose rate is the radiation dose per unit of time that affects humans from outside. Humans are constantly exposed to external radiation from natural radioactivity. This originates from natural radioactive substances (radionuclides) such as uranium, thorium or potassium (K-40), which are found everywhere in the ground and in building materials, as well as from radiation from outer space.

The measured local dose rate is given in microsieverts per hour (μSv/h).

Exhaust air (chimney)

For emission monitoring, there are permanently installed measuring points in the reactor's exhaust air stack and on the FRM II and campus site.

All relevant measured values can be queried via the operational control technology and are also transmitted to the Bavarian State Office for the Environment (LfU) (nuclear reactor remote monitoring system KFÜ, current measurement data from KFÜ). In addition, the LfU operates its own measurement network for measuring dose rates, as it does in the vicinity of all Bavarian nuclear facilities.

Waste water

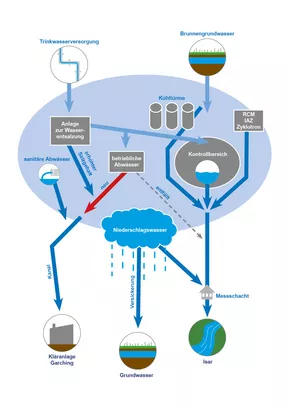

Well water: The required cooling water and flushing water is pumped from the well (fresh groundwater) and makes up the largest proportion (99.8 %) of the discharge volume into the Isar.

Discharge cooling: Here, the throughput volume of cooling water that is fed into the cooling system corresponds to the volume that is discharged from this cooling system. The properties of the fresh well water of the discharge cooling system are not changed, max. temperature increase of 10 K.

Cooling towers: The tertiary cooling system is used to dissipate the 20 MW of waste heat generated by the operation of the reactor into the ambient air. No heat input into the Isar.

Drainage: After evaporation via the cooling towers, natural minerals remain; these are filtered during drainage and then discharged into the Isar.

Control area FRM II & RCM: When a scientist washes his hands in the control area for purely hygienic reasons, it is collected in appropriate containers, although the water is not necessarily radioactive.

It is precisely defined what, how, when, where, by whom and with which device must be measured - in accordance with the Self-Monitoring Ordinance. Regular checks are carried out, sometimes in parallel, using samples and analyses from FRM II's own laboratories, the Federal Office for Radiation Protection, the State Office for the Environment and accredited laboratories.

The potentially low-level radioactive waste water from the controlled areas is treated using standard procedures (precipitation, filtering, oxygen treatment); in rare cases, the pH value is also adjusted.

Administrative and technical measures are in place to ensure seamlessly controlled discharge in compliance with the limit values. The final approval for the batch-by-batch discharge from the transfer tank into the Isar is given in writing by the plant chemist, radiation protection officer and plant management - the 6-eyes principle applies here!