Future Mo-99 irradiation facility

The radioisotope molybdenum-99 (Mo-99) which is required in nuclear medicine will be produced by the irradiation of uranium targets with thermal neutrons in the future Mo-99 irradiation facility. The uranium-235 (U-235) contained in the targets is split by the capture of thermal neutrons and provides a yield of 6.1% of all fission products of the unstable fission product Mo-99, whose daughter isotope is the desired radioactive technetium-99m (Tc-99m). The targets for the irradiation contain low enriched uranium (LEU).

Currently there are six major irradiation facilities for the production of Mo-99 / Tc-99m in the Western world, including four in Europe and one each in Africa and Australia. However, of these Mo-99-producing research reactors, five are already over 40 years old and three of them will be decommissioned until 2028. In the years 2008 - 2009, unforeseen, extensive and lengthy repairs were necessary in some of these reactors, which required a temporary shutdown. The absence of sufficient reserve capacity led to repeated major bottlenecks in the supply of Mo-99 between 2008 and 2010.

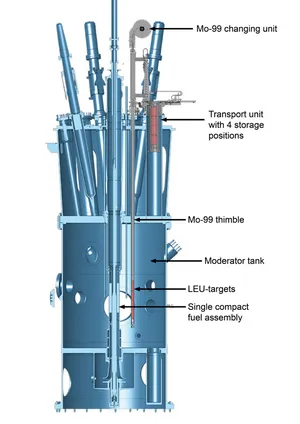

A feasibility study for the production of Mo-99 completed in 2009 showed the technical and logistical feasibility of building a Mo-99 irradiation facility at the FRM II. The design and construction of the facility are so realized that its operation will be possible parallel to the scientific use of the neutron source. With a planned maximum weekly production of approximately 16,000 Curie (Ci) Mo-99 activity – (this refers to the activity immediately after the end of irradiation) – the FRM II will be able to cover up to 50% of the European future demand. The completion and commissioning of the facility is foreseen for the upcoming years.

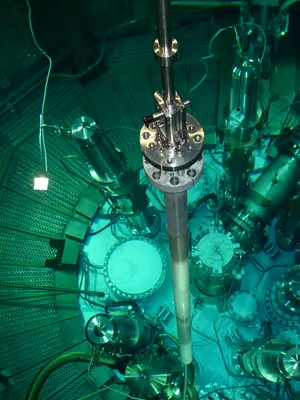

Following the decision to install a Mo-99 irradiation facility in the moderator tank of the FRM II, in February 2011, the thimble for future Mo-99 production was successfully mounted. The thimble is made of the durable and irradiation-resistant reactor material Zircaloy 4. With a diameter of nine centimeters and a length of five meters, in future it will include 2 independently loadable, identical irradiation channels and enable the simultaneous irradiation of 2 x 8 so-called plate targets. The targets are positioned at a distance of about 45 cm from the fuel element, and thus close to the thermal neutron flux maximum. Each target contains 20 g of low-enriched Uranium (19.75 % enrichment of U-235, LEU).

In 2013, a 10 tons freight elevator was installed to transport the irradiated targets within the reactor building. Currently, loading, unloading and cooling of the targets are tested in a 1:1 scale mock-up.

The manufacturing and installation as well as the commissioning of the future Mo-99 irradiation facility are planned for the upcoming years. The total cost for the construction of the Mo-99 facility amounts to approximately € 5.4 million. Additionally, the necessary research and development activities for the optimization of Mo-99 irradiation are supported by the Federal Ministry of Health through a € 1.0 million contribution.

Until the start of irradiation, however, substantial development work is still required. This includes, amongst other things, the completion of two test stands, which represent the essential components of the future irradiation facility built on a scale 1:1. They serve to verify the technical construction, to test the manufacturability of the irradiation channels, and finally to test the handling steps during the irradiation.

Simulation of the cooling channel return flow

The smaller of the two experimental mock-ups is a replica of the cooling channel return flow, which will later house the targets for irradiation. The channel has original dimensions, but is only 2 m long and made of Plexiglas so as to be able to observe the flow of the cooling water. Using dummy targets the behavior at high volume flow is investigated here.

Simulation of the entire Mo-99 irradiation facility

The large experimental mock-up is the replica of the complete cooling channel unit with the two irradiation channels as they are to be introduced later in the already mounted moderator tank thimble. For reasons of cost, the channels are made up out of stainless steel and not Zircaloy as they will later. This experimental mock-up is used to test loading and discharging procedures of the targets as well as cooling processes.